Many Grumman owners fly fewer than 25 hours a year — and wait until the 50-hour mark or even their annual inspection to change the oil. But Lycoming and leading engine experts say that delay could be shortening your engine’s life. Here’s why calendar-based oil changes are critical, especially for low-use aircraft.

Why Corrosion Happens Even When You’re Not Flying

Every time your engine runs — even for a short flight — it generates water vapor, sulfur, and acidic combustion byproducts. If you don’t fly long enough to burn that off and then let the plane sit for weeks, these chemicals begin attacking your engine from the inside out.

The camshaft and tappets are particularly vulnerable. According to Lycoming, “As the engine is run after rust has formed, the rust becomes a very fine abrasive causing internal engine wear.”

“As the engine is run after rust has formed, the rust becomes a very fine abrasive causing internal engine wear.”

— Lycoming SB 480F

⚙️ The Real Cost of Neglecting Your Engine

An overhaul for your Lycoming O-320 or O-360 engine can easily run into tens of thousands of dollars. Recent pricing from reputable overhaul providers gives you an idea of potential costs:

- Lycoming O-320 engine overhaul: Approximately $25,000–$32,000

- Lycoming O-360 engine overhaul: Approximately $30,000–$36,000

(Pricing source: Recent industry averages via Aviation Consumer, Trade-A-Plane, and direct overhaul shop estimates, May 2025.)

Keep in mind, these prices can go even higher if corrosion or excessive wear is discovered—especially common if oil changes and preventive maintenance have been neglected.

In contrast, regularly scheduled oil changes (recommended every 4 months or 25 flight hours, whichever comes first) combined with the proactive use of protective additives like CamGuard cost a tiny fraction of an overhaul. It’s truly cheap insurance for your engine’s longevity.mage or parts replacement. For many Grumman owners, protecting that investment with timely oil changes is a no-brainer.

Why Your Engine Isn’t Like Your Car’s

Your Lycoming engine runs on leaded fuel, has an exposed camshaft, and often sits unused for weeks. That’s a recipe for acid formation and metal degradation. Automotive oil change logic doesn’t apply here. These engines require proactive maintenance — especially when they aren’t flying often.

That’s why Lycoming recommends oil changes every 4 months or 25 hours, whichever comes first — not 50 or every annual.

Protect Your Camshaft with CamGuard

The camshaft is one of the most expensive and failure-prone components in low-use engines. Once corrosion sets in, it’s game over without a full teardown.

Adding CamGuard to your oil change routine offers:

- Rust and corrosion protection

- Wear reduction

- Better long-term preservation between flights

At just $28, it’s cheap insurance.

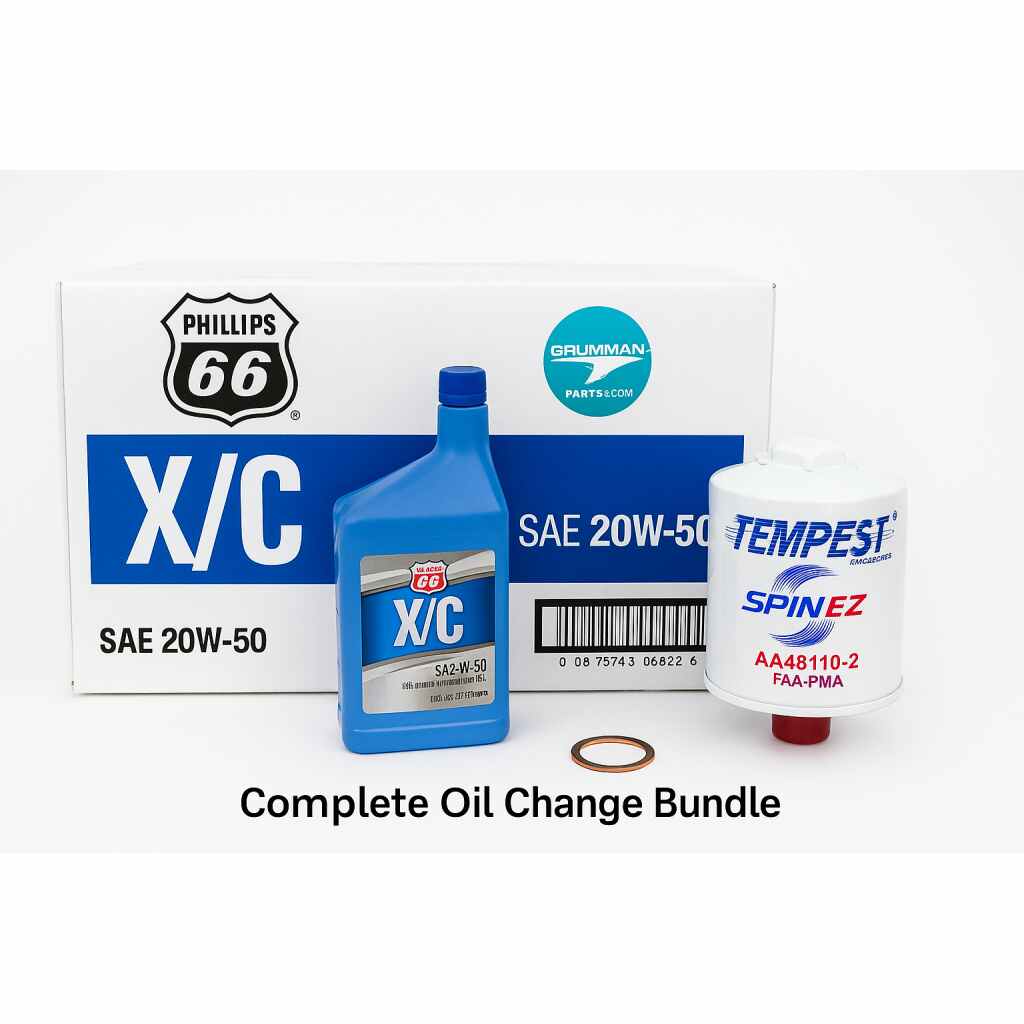

We’ve bundled everything you need into one Grumman-specific oil change kit:

12 Quarts Phillips 20W50XC Aviation Oil

Tempest AA48110-2 Filter

Lycoming crush washer

Optional: CamGuard

Resources & Further Reading

Lycoming on Low-Time Engine Risk

The Cam Problem – Aviation Consumer