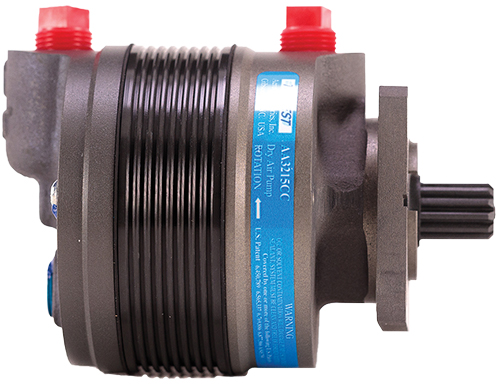

Description

Tempest overhauled Grumman Vacuum Pump fits the following:

| AA-1, AA1A Yankee, Trainer | Lycoming O-235-C | AA3215CC | 215CC, AA215CC, AA3215CC |

| AA-1B Trainer, TC | |||

| AA-1B-0219 and Up Except AA1B-243 and 246 thru 250 | Lycoming O-235-C | AA3215CC | 215CC, AA215CC, AA3215CC |

| AA-1B-0379 and up | Lycoming O-235-C | AA3215CC | 215CC, AA215CC, AA3215CC |

| AA-1C, T Cat / Lynx (Model Years 1977/1978) | Lycoming O-235-L | AA3215CC | 215CC, AA215CC, AA3215CC |

| AA-5 Traveler | Lycoming O-320-E | AA3215CC | 215CC, AA215CC, AA3215CC |

| AA-5A Cheetah | Lycoming O-320-E | AA3215CC | 215CC, AA215CC, AA3215CC |

| AA-5B Tiger | Lycoming O-360-A4K | AA3215CC | 215CC, AA215CC, AA3215CC |

| GA-7 Cougar | Lycoming O-320-D | AA3215CC | 215CC, AA215CC, AA3215CC |

Tempest is a renowned dry air pump provider, boasting FAA-PMA approval. With a comprehensive range of options, Tempest ensures reliability and quality in their product line.

One notable feature of Tempest dry air pumps is their monolithic construction. This design choice enhances durability and eliminates the risk of leaks. Additionally, these pumps are equipped with a wear indicator port (WIP™), which allows for internal observation of the pump’s vanes. This innovation aids in assessing the condition of the pump and helps avoid unscheduled maintenance caused by exceeding the pump’s life cycle.

Tempest dry air pumps incorporate finned stators to improve cooling. Furthermore, the internal wear surfaces of the stator are treated with an “ultra-hard” finish, reducing friction and prolonging the pump’s lifespan.

The new models of Tempest dry air pumps feature a closed coupling area and a patented “LRT” diverter. These design elements prevent pump contamination from external sources, ensuring reliable and efficient operation.

Aviation maintenance technicians worldwide have recognized Tempest as the preferred choice for dry air pumps. The exceptional construction, advanced features, and reliable performance of Tempest pumps have garnered the trust and preference of professionals in the industry.

In the case of overhauled pumps, Tempest takes excellent care in the restoration process. When a core is received, all carbon components are discarded and never reused.

In conclusion, Tempest dry air pumps offer a wide range of benefits and features that make them highly sought after by aviation maintenance technicians. The combination of innovative design, meticulous assembly, and rigorous testing procedures ensures the production of reliable and top-quality pumps. Whether you choose a new or overhauled pump from Tempest, you can be confident in its performance, durability, and adherence to industry standards.

Reviews

There are no reviews yet