Wheels, Tires, and Inner Tubes

Tire and Inner Tube Selection Considerations and Maintenance for Light Aircraft General Aviation Owners and Operators

Introduction

As an aircraft owner or operator, you know that your tires and inner tubes are vital components of your aircraft’s landing gear. It’s essential to choose the right tires and tubes and maintain them properly to ensure the safety and performance of your aircraft. In this blog post, we will discuss tire and inner tube selection considerations and maintenance for light aircraft general aviation owners and operators.

Tire Selection Considerations

- Size and ply rating: First and foremost, consult your aircraft’s Pilot Operating Handbook (POH) or Aircraft Maintenance Manual (AMM) for the correct tire size and ply rating. The ply rating indicates the tire’s load-carrying capacity and its resistance to punctures. For most light aircraft, a 4-ply or 6-ply tire is sufficient.

- Tread pattern: Tread patterns on aircraft tires come in a variety of designs, such as ribbed, smooth, or chined. Ribbed tires provide better traction, while smooth tires offer less rolling resistance, which can improve fuel efficiency. Chined tires have a unique design that deflects water, reducing the risk of hydroplaning.

- Bias or radial: Bias-ply tires have cords that crisscross, giving them more flexibility and a lower cost. Radial tires have cords that run perpendicular to the tread, providing better heat dissipation and longer wear life. However, radial tires are typically more expensive.

Inner Tube Selection Considerations

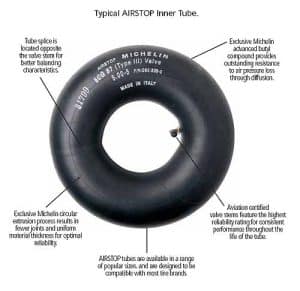

- Material: Inner tubes for aircraft tires are typically made from natural rubber or butyl rubber. Natural rubber tubes have better low-temperature performance and elasticity, while butyl rubber tubes offer better air retention and resistance to ozone and ultraviolet light.

- Valve type: Choose the appropriate valve type for your aircraft’s rims. Common valve types include TR-67 (bent), TR-87 (right angle), and TR-218 (straight).

Tire and Inner Tube Maintenance Tips

- Regular inspections: Inspect your tires and inner tubes during every pre-flight walk-around, checking for cuts, abrasions, tread wear, and foreign objects embedded in the tire. Replace any damaged or worn tires immediately.

- Proper inflation: Check tire pressure with a reliable gauge during every pre-flight inspection and maintain the recommended pressure listed in your POH or AMM. Over-inflated tires can lead to premature wear and reduced traction, while under-inflated tires can cause overheating and possible blowouts.

- Balancing: Balance your aircraft’s tires to minimize vibration and uneven wear. This can be done with the help of a professional mechanic or using a portable balancing tool.

- Storage: If your aircraft is going to be stored for an extended period, place it on jacks to prevent flat spots from forming on the tires. Store the aircraft in a cool, dry, and well-ventilated area, away from direct sunlight, to prolong the life of the tires and tubes.

- Periodic replacement: Even if your tires and inner tubes appear to be in good condition, it is essential to replace them periodically. Most manufacturers recommend replacing tires every 5-7 years and inner tubes every 3-5 years, depending on the usage and storage conditions.

Conclusion

Tire and inner tube selection and maintenance are crucial aspects of aircraft ownership and operation. By choosing the right tires and tubes for your light aircraft and maintaining them properly, you can ensure the safety and performance of your aircraft, ultimately providing a smoother and more enjoyable flying experience.

Showing all 25 resultsSorted by popularity

-

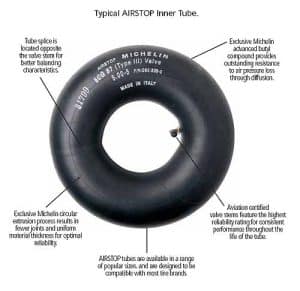

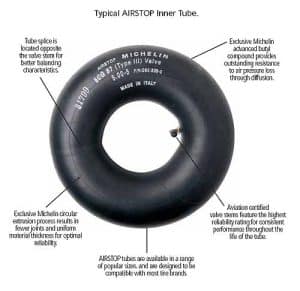

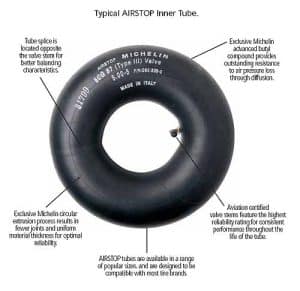

Best Aircraft Inner Tubes

Price range: $109.95 through $115.95 -

Grumman Tires – Budget Friendly Air Hawk

Price range: $104.95 through $178.00 -

Air Trac® Tires for Grumman Aircraft

Price range: $103.00 through $123.00 -

Grumman Aircraft Wheel Bearing AA1 – AAG5

Price range: $71.50 through $79.99 -

New Grumman Wheel Seal Kits

Price range: $94.75 through $110.96 -

Leak Guard Inner Tubes 90 Degree Convenience Stem

Price range: $92.24 through $115.00 -

Grumman Aircraft Wheel Bearing Cup AA1 – AAG5

Price range: $38.75 through $49.00 -

Good Year Flight Special II

Price range: $160.00 through $175.00 -

Desser Monster Retreaded Tires for Grumman Aircraft

Price range: $98.95 through $131.95Out of stock

-

Good Year Flight Custom III Tires

Price range: $270.00 through $359.00 -

Condor Aircraft Tires for Grumman

Price range: $141.95 through $196.95Out of stock

-

Grumman Yankee Main 15×6.00-4ply Airtrac Tire: High-Quality, Durable & Reliable Performance for Aircraft

$165.00 -

16OZ. SHAKER BOTTLE OF TUBE TALC

$26.80 -

SHC100CTG EXXON MOBIL GREASE 13.4oz Tube

$19.50 -

Goodyear Flight Custom III 6.5×8 (8ply)

$500.00 -

Michelin Airstop 6.5-7-8 High-Quality Inner Tube

$158.00Available on backorder

-

Michelin Airstop 15×6.00-6 Inner Tube – High-Quality, Durable Tire Tube for Enhanced Performance

$154.95Out of stock

-

Michelin AirStop 6.00×6 Main Gear Inner Tubes for Grumman Aircraft – High-Quality & Durable

$153.95 -

Desser Retreaded Tires for Grumman Aircraft

Price range: $68.00 through $99.99Out of stock

-

GoodYear Flight Custom III 5.00-5 (4Ply)

$255.00 -

Michelin Airstop 5×5.00 High-Quality Inner Tube for Enhanced Performance

$195.00Out of stock

-

GOODYEAR FLIGHT CUSTOM III TIRE 6.00-6 6 PLY 606C66-8

$329.00 -

Michelin Air 15-6.00-6ply Tire

$237.00 -

Retread 6.00×6 Tube Type Tire – 4 Ply Durable Aircraft Tires

$99.00Out of stock

-

Airtrac 5×5.00 6ply High-Quality Durable Tire for Optimal Performance

$107.00